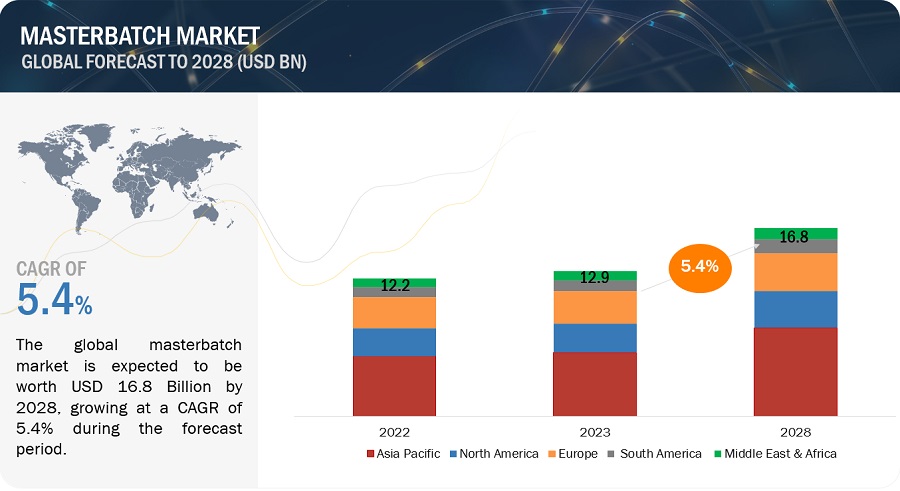

Things about Masterbatch

Wiki Article

See This Report about Masterbatch

Table of ContentsThe Main Principles Of Masterbatch Facts About Masterbatch UncoveredThe 15-Second Trick For MasterbatchFascination About MasterbatchThe Single Strategy To Use For Masterbatch

is a dye in the form of granules of numerous forms for tinting the polymer at the stage of development of a polymeric mass in the melting process. For the most part items from polymers tinted straight on the stage of production of the finished item. For tinting in the structure of the feedstock (polymer) masterbatches (granular dyes) are introduced.What the distinction in between typical focuses and also masterbatches (or superconcentrates)? The percent of pigment in the polymer base. If the concentrate proportion of the pigment is greater than 20-30%, you can call it as "masterbatch" (or superconcentrate), that is, a concentrate with a high content of pigment. The process of adding of masterbatches in the initial polymer basic material is the least complicated contrasted to various other techniques of coloring plastics.

In the manufacturing procedure we use imported organic and also inorganic pigments, that do not migrate to the surface of the material, have a high-precision colour recreation and resistance to the temperature level program of handling. Our raw parts are not exposed to UV light as well as weathering. that you can purchase from us might have from 30% to 70% Ti, O2 (titanium dioxide), furthermore we can provide you a milky white or snow-white tones of masterbatches.

The Buzz on Masterbatch

that we create have high carbon material. They have as much as 60% of top notch carbon black. Carbon focuses have outstanding diffusion and also immune to thermal impacts, they are economical items. This type of products we generate have a carbon material from 20% to 60%, besides the different carbon concentrates give the ended up item a haze or sparkle.The benefits of our color masterbatches: Offer consistent shade of blend Do not contaminate and do not dust workplace when altering shade Supply an easy cleansing of the functioning equipment Create a small quantity of waste They are extremely economical in dose We can establish any kind of interesting shade for your item as well as to provide to masterbatch some special impacts: metallic, gold, bronze or silver shades, fluorescent and also pearlescent, "marble" as well as "granite chips" structure etc.

Not known Factual Statements About Masterbatch

By raising the dispersion level of titanium oxide bits in the masterbatch, the reflective buildings of titanium dioxide can be revealed a lot more properly, as well as its power can be shown in reflective applications such as LED reflectors that require high reflectivity.Acquire the item just from a developed with a tested track record of read manufacturing and handling highly-concentrated white masterbatch. It ought to fit the requiring applications, for instance, extrusion covering, as well as low-end applications in which high degrees of filler are combined to provide suitable and cost-effective services. If you are seeking white masterbatches, after that do not go additionally.

The Basic Principles Of Masterbatch

It is helpful to keep the chemical stability of the pigment. When the pigment is directly used, because the pigment straight contacts the air throughout storage space as well as use, the pigment may absorb water, oxidize, etc, and after the color masterbatch, given that the resin service provider separates the pigment from the air and moisture, the top quality of the pigment might not transform for a long-lasting.

With making use of polypropylene nonwoven artificial fibers, the product gets the desired buildings and stamina to ensure higher toughness. Along with the communicating characteristics, the masterbatch additionally supplies intricate shade and also performance on products. With the ability to preserve prolongation, tensile toughness, increase bonding in addition to rise rate, increase elasticity to increase the printability of bags, PP non-woven plastic resins are frequently used and necessary in the PP woven bag manufacturing.

The 30-Second Trick For Masterbatch

ABS plastic is rather very easy to collaborate with and also has a low melting point making it a terrific option for contemporary molding strategies like plastic shot or even 3D printing. In addition, check that the inexpensive of abdominal muscle plastic likewise boosts its popularity in several application locations such as automobiles, electrical equipment, sporting activities equipment, toys, building and construction, ... Used in vehicle components of vehicles and also automobiles to help in reducing weight: dashboard, belts, safety belt, door linings, door manages, handles, ... Application in household as well as daily, Used in the manufacture of tools such as control board, hoover, food handling makers, refrigerators, ...Because of this, polymers utilized outdoors commonly require UV protection and also weather condition immune pigments. The light maintaining system needs to be thought about with each other with the pigment formulation and the fastness requirements specified for the end product (masterbatch). Light Fastness is a procedure of the shade fastness of plastic objects when made use of in interior applications.Report this wiki page